Comprehensive Solutions and Components for Monitoring Processes in Biogas Plants

Biogas digesters operate under extreme conditions, where explosion risks, gas-tightness, and contamination hazards are constant concerns. As the exclusive Canadian representative for Max Müller AG, CL Valve Process Solutions proudly offers cutting-edge systems designed to meet stringent safety standards. Products like explosion-proof CHEMLUX® light fittings and VIDEOLUX® cameras ensure secure monitoring in hazardous areas, while gas-tight VETROLUX® sightglasses prevent leaks and enable precise process control. With Max Müller AG’s 50+ years of expertise and CL Valve Process Solutions’ dedication to innovation, we deliver robust, ATEX-certified solutions that enhance safety, protect workers, and ensure compliance with global safety regulations.

Comprehensive Solutions for Biogas Plant Monitoring

Why Safety Matters

Biogas digesters require reliable systems to mitigate risks, optimize performance, and ensure operational safety. Max Müller AG’s cutting-edge products enable seamless process surveillance and risk management in these high-stakes environments.

Key Products and Features

- VETROLUX® Sightglasses

- Durable and adaptable for various fermenter materials.

- Compatible with accessories such as wipers, cameras, and foam detectors.

- CHEMLUX® Sightglass Light Fittings

- Explosion-proof and certified for hazardous zones.

- Available in LED or halogen options for optimal lighting.

- VIDEOLUX® Camera Systems

- State-of-the-art, explosion-proof cameras.

- Designed for remote and on-site process monitoring with advanced zoom capabilities.

- VETROLUX® Wipers and Spraying Devices

- Built for extreme conditions with manual, pneumatic, or electric operation.

- Enhances visibility and cleanliness in hazardous areas.

Applications Beyond Biogas

Max Müller AG’s solutions extend to various industries, including:

- Chemical Plants: Ensuring safety in high-risk production environments.

- Hazardous Material Facilities: Offering robust monitoring systems to prevent contamination and manage risks.

- Food Manufacturing: Supporting strict hygiene and safety requirements.

These versatile solutions cater to the unique challenges of demanding industries, making them a trusted choice for process monitoring.

Trusted Expertise Since 1982

At CL Valve Process Solutions, we’ve built a reputation for delivering reliable and innovative monitoring systems. Partner with us to ensure safety and operational excellence in your biogas and industrial applications.

Contact Us

For inquiries, email us at info@clvalve.ca.

Featured Product Configurations

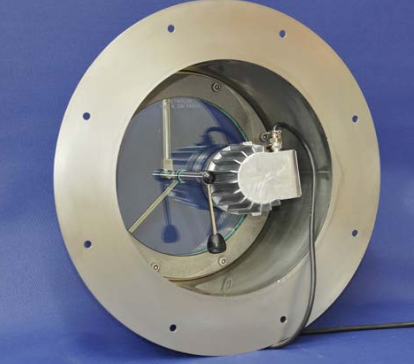

1. VETROLUX® Sightglass System

- Specifications: Similar to DIN 28120, PN 0, featuring:

- Adapter for direct wall mounting of fermenters.

- Window wiper, spraying device, CHEMLUX® light fitting, and VIDEOLUX® camera system.

- Certifications: Ex d IIC T3 Gb, Ex II 2 G + D.

- Additional Features: Integrated timer (Type “V”).

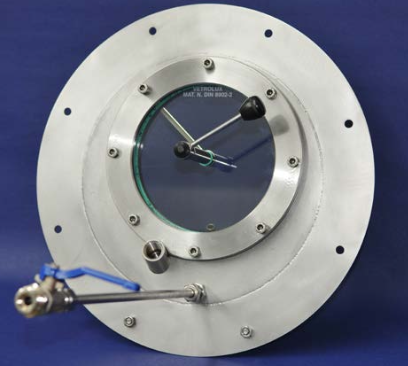

2. Foam Sensor Integration

- Sightglass with an inlet for foam sensors.

- Includes centrally operated wipers and spraying devices.

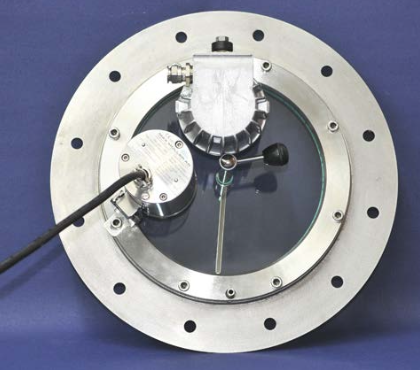

3. Explosion-Proof Camera Systems

- VIDEOLUX® stainless steel cameras (Type Mini-Zoom).

- Hazard Rating: Ex d II B (C), Ex II 2 G + D.

- Compact and durable design for extreme environments.

Watch the System in Action

View our video demonstration:

Watch now on YouTube

Note: All dimensions are in mm. Product specifications are subject to change without prior notice.